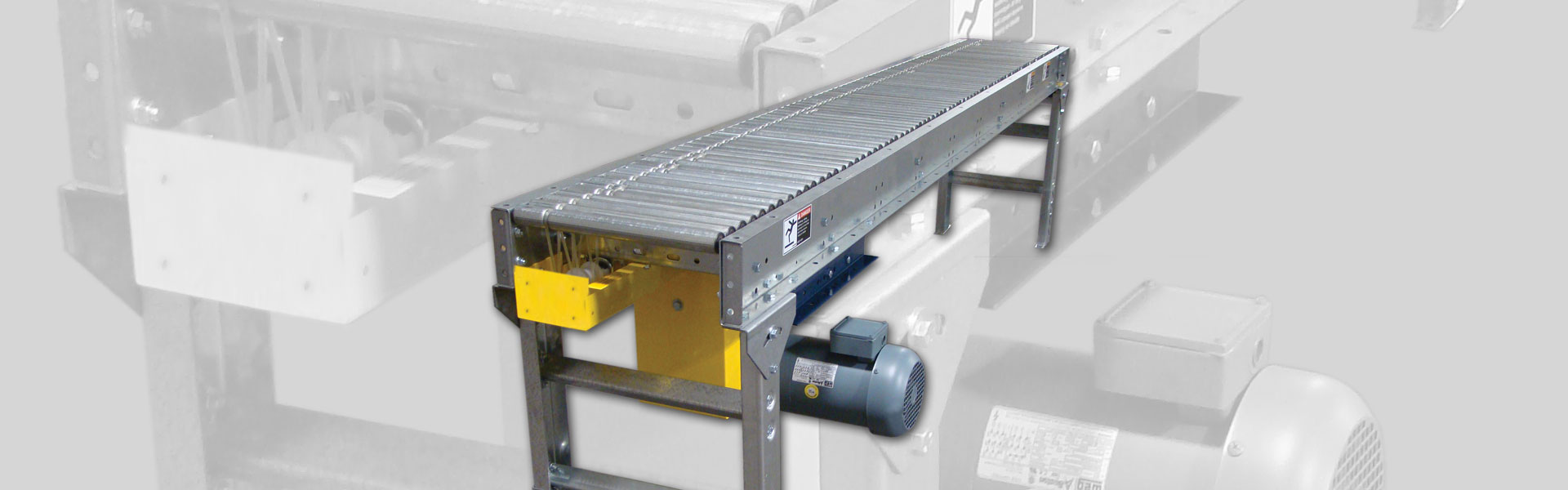

Case conveyor systems move boxes, cartons, packages, and cases of products throughout production, packaging, sorting, warehousing, and shipping areas. They are typically measured in “Between the Frame” (BF) dimensions and come in all shapes and sizes. Case conveyors are typically between 16-34 between frame and routinely meet operational, and throughput and sortation requirements for manufacturers, warehouses, fulfillment operations, and more, including:

- More efficient use of floor space

- Reduced forklift traffic

- Reduced employee traffic

- Faster product movement

- Ergonomic picking

- Fast, accurate sorting and staging by many variables

Explore the available conveyor spare parts from these leading OEM manufacturers:

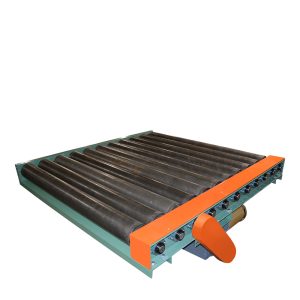

Pallet conveyor systems move heavier loads throughout various plant or warehouse areas in a more ergonomic and safe process. Employee heavy lifting is virtually removed from operations. These systems are typically motorized and can feature turntables, junctions, lifts, loading, and unloading stations. Pallet or skid sizes and load weights are critical measurements for determining your pallet conveyor needs. Pallet conveyors are typically between 36-65″ on chain centers and roller width and offer many benefits, including:

- Greater flexibility for transporting heavy pallet loads

- Lower product moving costs

- Ergonomic load transportation

- Reduced product damage

- Reduced forklift traffic

- Faster product movement

- Optimum flow between palletizing and stretch wrappers

Explore the available conveyor spare parts from these leading OEM manufacturers:

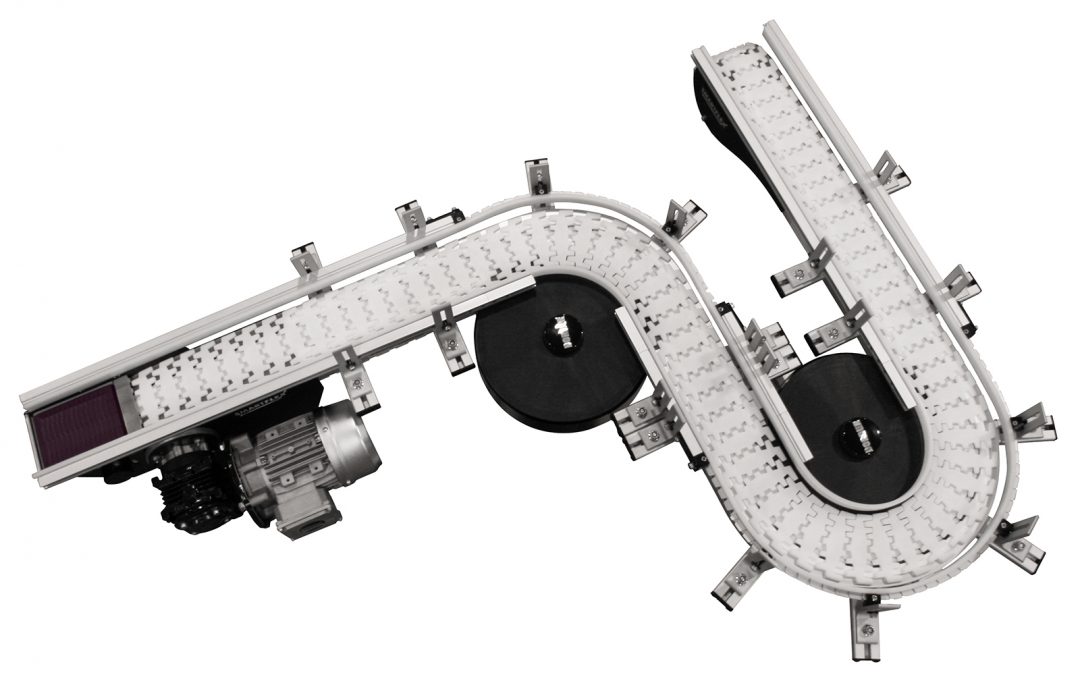

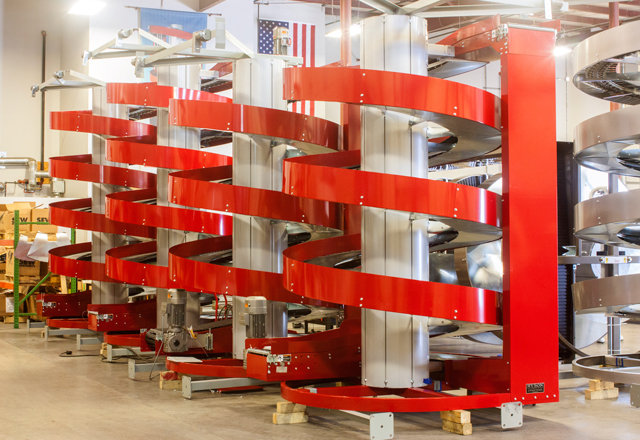

Specialty conveyor systems are custom-designed for more unique or demanding material handling solutions. They facilitate individual product handling, specialty containers like bags, areas with limited space, extreme temperatures, high speeds, or delicate products. Specialty conveyors can also move units in various directions, like vertically, spirally, and more. They benefit manufactures, shippers, and others with:

- Meeting unique applications

- Meeting clean room requirements

- Small turn radius solutions

- Reduced handling

- Product transfers

- Increased accessory adaptability

- Stainless steel options

Explore the available conveyor spare parts from these leading OEM manufacturers:

Have Questions?

ConveyorSpareParts.com has extensive product and system knowledge, offering assistance with parts, repairs, and potential in-stock solutions. For inquiries, including specific parts or drawings, contact our dedicated and supportive staff.

Exceptional Help

Our team has the vast product and system knowledge to help you from questions to ordering to scheduling your parts arrival for timely repairs. All RFQ’s are responded to within 24 hours. Once an order is placed, a confirmation email is sent with the estimated ship date and when the product is sent our team follows up with the tracking numbers.

Secure Packaging

Your order is securely packaged and handled carefully so parts arrive intact, undamaged, and ready to install for fast repair turnaround times. All orders contain a packing slip with all part numbers identified.

Best Price

ConveyorSpareParts.com offers competitive pricing on all our conveyor parts from leading brand manufacturers so you know you’re saving money with each order.